Uses of drum pallets

17 Mar 2014

Drum pallets are specially designed for holding drums filled with liquid. They have a number of features to allow drums to be securely fixed and handled in a way that is not possible with normal pallets. Typically, drum pallets are built to hold up to four drums at a time. However, pallets designed for anything from two to eight drums are available, and even single-drum pallets can be easily purchased to allow an individual drum to be conveniently lifted and transported.

Transportation and Export

One of the key uses of drum pallets is simply to make it easier to transport and export liquid products contained in drums. In much the same way as other pallets are used to transport a wide range of goods, so drum pallets are used to transport drums of liquid. The use of a pallet allows multiple drums to be used at once, and makes lifting and moving the drums easy with standard machines and equipment such as forklifts.

There are a number of reasons drum pallets are used for this purpose as opposed to normal pallets. They are specialised for drums in a number of ways. In a nutshell, drum pallets are designed to allow drums to be held more securely and provide precautions in case of a spillage.

Spill Containment

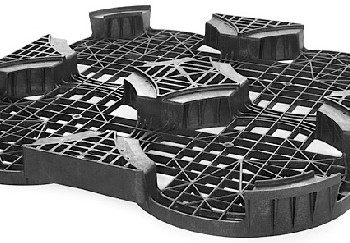

Many plastic pallets are also designed to contain any spills that might occur. Drums are stood on a grate that allows any spillage to seep through rather than pool and spread. Beneath this, the drum pallet incorporates an enclosed container that spills can safely collect in and not spread beyond the pallet.

There are several advantages of these spill-containment precautions. They make it easier for any spills to be cleaned up, as all spilled fluids will be contained within the pallet and can easily be taken away for disposal. Without these precautions, a spill could also stain or damage other products and the workplace floor. The use of a drum pallet with precautions against spills will prevent this.

Durability and Longevity

Drum pallets are designed to be durable and to resist the adverse conditions that can sometimes come with transporting drums. As well as providing spill containment, they are also spill-resistant. While wooden pallets may be damaged by fluid spillage, drum pallets are almost always plastic pallets. Plastic is less prone to fluid damage as it is waterproof and does not react with many chemicals. As such, the pallet can stand up to conditions where there is a risk of spillage as well as other moist conditions.

Of course, drum pallets are also designed to be durable in general. Certainly, they will be built to withstand the weight of full drums as well as difficult conditions during transportation or when used on a factory or warehouse floor. The fact that drum pallets are almost universally made of plastic is an advantage. The plastic construction is not prone to rotting and has fewer joins than a wooden pallet, making it less likely to come apart because of wear and tear.