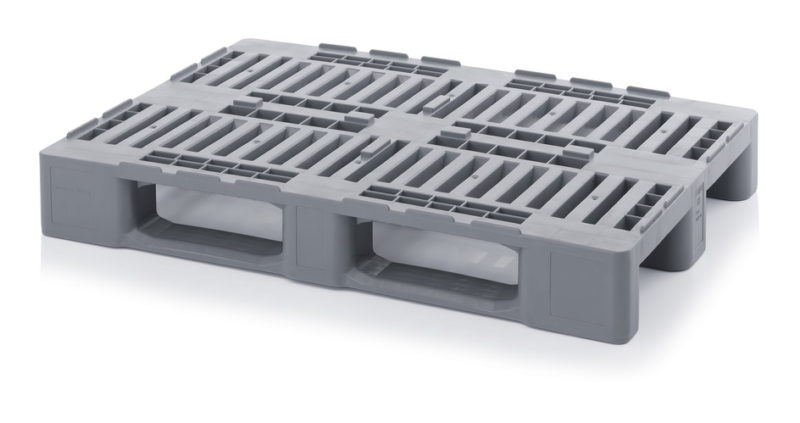

Custom Built Plastic Pallets

22 Feb 2018

Plastic pallets have lots of advantages, including durability, ease of cleaning and being impervious to moisture and weather. Custom built plastic pallets can offer even more flexible benefits when they are designed and constructed with certain factors in mind.

Tools for the Job

Custom plastic pallets can play an important role in branding and marketing, as they can go straight from warehouse to shop floor. This can mean significant cost savings and convenience in shipping and handling, but the pallets have to be absolutely right for the job.

In selecting a manufacturer, choose an organisation that has solid expertise in producing custom built plastic pallets. Make sure the company you select has the equipment for blow moulding, thermoforming and injection moulding to keep your options wide open. Some designs require a specific process, but in general thermoforming is good for small quantities, and for large volumes injection moulding is more suitable. Searching online for custom plastic pallets should bring up some suitable companies.

When it comes to designing the pallet, a reputable company will have CAD software or similar for producing technical drawings of the design. This is where specific features need to be considered, especially those which will play a part in marketing and branding. Think about what the pallet needs to flexibly serve all the needs of its supply chain.

Co-operation with Manufacturer

Work closely with your manufacturer for quality control and to ensure features such as forklift slots, recessed rings and the appropriate load capacity are included. As pallets can be heavy, avoiding accidents is important, and it is a good idea if the pallets are designed and constructed to meet the relevant British Standards. Considerations include the environment the pallets will be used in, the loads they will carry and how the pallets will be moved. The pallet designer should know which British Standard applies to the pallet being designed and how to ensure the pallet is fit for its intended use.

Safety

Under the Provision and Use of Work Equipment Regulations 1998, pallets must be suitable for purpose, be maintained and meet requirements when inspected. Safety is of paramount importance, and the pallets must be stable when stacked, racked or stored. When pallets are stacked with full loads, the bottom pallet must be able to bear the weight of the entire stack without slipping or fracturing. There may a certain way that the pallets must be stacked for optimum stability, and this should be indicated clearly to avoid errors. Pallets that are moved by forklift may need two or four entry points. When moving stacked pallets, care must be taken and the height of the load should not exceed the pallet’s longest base measurement. Racking can place pallets under stress, so pallet supports must be adequate.

Custom built plastic pallets can play a vital role in the successful transport, storage and promotion of your goods. However, there are a number of elements that need to be taken into consideration when designing and manufacturing your own pallets, and it is worth taking your time to ensure that all the necessary features are accounted for. They must conform to the appropriate British Standard and be safe to stack and move when fully loaded.